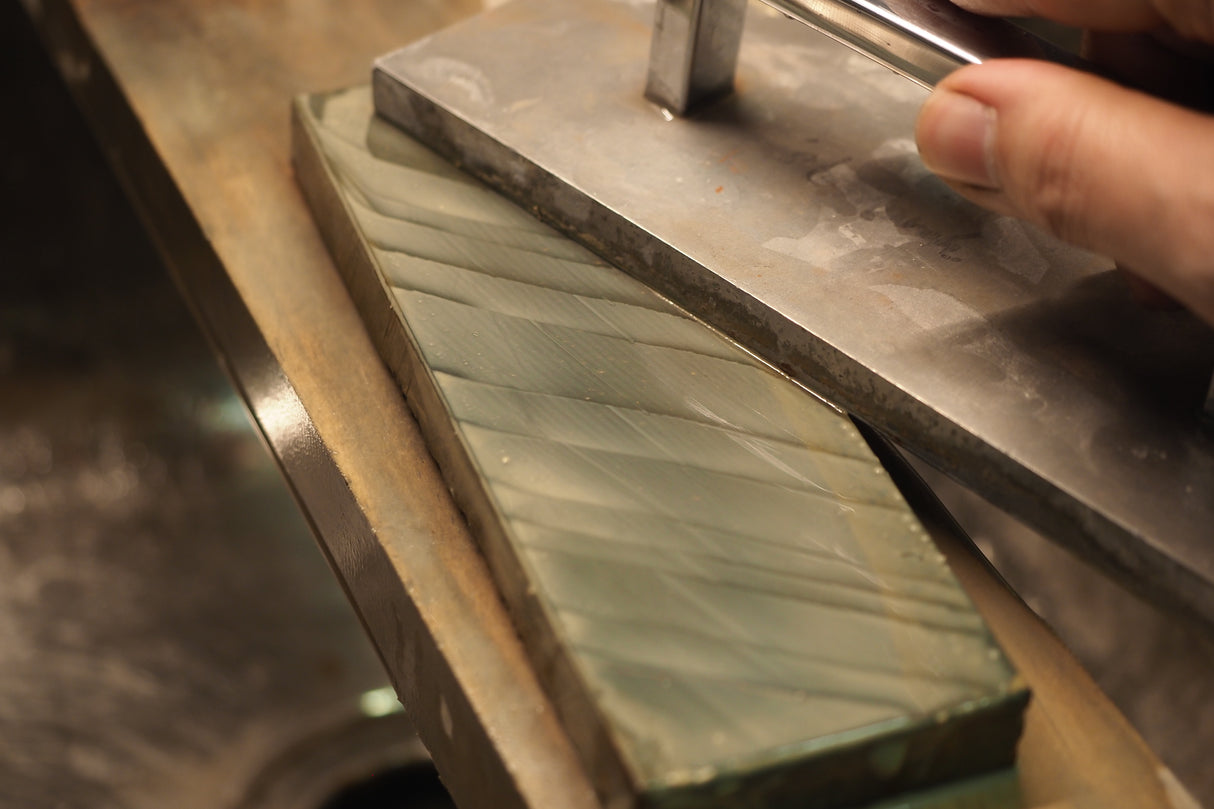

Jnat (Japanese Natural Whetstone) - Shohonyama Awasedo Mizukihara M1

Couldn't load pickup availability

Length: 180mm

Width: 63mm

Height: 23mm

Weight: 600g

Hardness: ★★★★☆

Maintenance for natural whetstones

Do not soak in water. Water penetrates into the layer of stone, causing it to crack.

Recommended to protect the sides with cashew coating from cracking.

After use, wash with running water, wipe, wrap the stone with dry cloth and leave in a cool place. Please avoid direct sunlight.

Complimentary cashew coating service

Only available for natural whetstones you purchase from us. We offer a cashew coating for those taking extra care of the stones. It takes a week for pickup as we apply cashew 3 times on the sides and it needs to be completely dry.

Why is Jnat (Japanese natural whetstone) so valuable?

Japanese natural whetstones are the final destination for those seeking the best result of sharpening. At Kaz’s knife and Kitchenware, we have a variety of natural stones, most of which are Kyoto’s Shohonyama Awasedo, known as the highest-grade finishing stones. Many of the sites for natural whetstones have been closed, so natural whetstones available in today’s market are limited in number, and the prices are expected to rise due to its scarcity value.

Some trivia of Jnat

The natural whetstones suited for finishing purposes are mainly siliceous slate and siliceous shale. These are further narrowed down to the ones that meet several requirements such as hardness, evenness of abrasive and absorption of water. Geographically, it is proven that Kyoto and its surrounding have the ideal stratum for natural whetstones, where layers of clay and radiolarian have slowly accumulated on the ocean floor in the equatorial regions at a rate of 1mm per a thousand years since the ancient Permian period (about 250 million years ago). Then, it traveled to the current location in Japan through crustal movement on the ocean plates.

Why do we sharpen with Jnat?

Popularity of Jnat has grown because of the beautiful finishing results on the blade surface. It creates the distinct contrast between the edge line and cladding steel as well as natural luster that evenly appears throughout. Exceptional sharpness is also the point why users prefer Jnat. Furthermore, its delicate abrasive performance prevents excessive grinding on the steel, which often leads to rust developed on scratches. Overall, Jnat enables more precise and even-toned sharpening.

-

my_fields.specification-

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Frequently Asked Questions

Shipping

What countries do you ship to?

What countries do you ship to?

We ship orders from Melbourne. As well as everywhere within Australia, we ship to United States, Canada, New Zealand and some European countries. If your area is not listed in the checkout, please let us know.

How long will it take to receive my order?

How long will it take to receive my order?

Shipping timeframe depends on Australia Post. Parcel post shipping normally takes 1-4 days while express post shipping ensures more prompt delivery. International shipping times depend on the destination (estimated at checkout).

Do you bear import tariffs?

Do you bear import tariffs?

No, import tariff and any fees accompanying have to be paid by customers.

Returns and Refunds

How do I return a product?

How do I return a product?

First if all, please contact us by email: info@kazsknifeonline.com.au.

Items must be returned within 30 days after receiving your order. Items must be returned in the same condition in which they were received, be unused, including all the original packaging.

Upon items returned and confirmed to be resalable, we will process a refund for the item.

How long will it take to receive my refund?

How long will it take to receive my refund?

It usually takes 3-5 business days from the time we process the refund until you receive the money.